Storopack PAPERplus

TwinSource, the Minnesota leader in packaging products, has partnered with Storopack to distribute PAPERplus’ material producing systems.

PAPERplus from Storopack utilizes numerous systems to transform paper rolls into packaging material. From small items to large industrial-sized items, there is a PAPERplus product available that will provide an economical and efficient solution to satisfy your needs.

PAPERplus materials are constructed from recycled and virgin paper. They are durable enough to be used many times and are recyclable, ensuring they are both economical and environmentally friendly.

PAPERplus Classic

PAPERplus Classic’s versatile functionality means it has the strength and durability to handle large objects, as well as the bulk needed for superior void-fill and cushioning. There are two types of PAPERplus Classic machines available as well as numerous paper ranges that provide paper pads for a variety of packing solutions:

PAPERplus Classic: The PAPERplus Classic machine produces paper mattresses that work well in any box size.

PAPERplus GE: The PAPERplus GE machine creates smaller paper mattresses that can still work in any box size but are optimized for small and medium boxes. The smaller size ensures a lower in-the-box cost and also speeds up the loading and handling time.

Multiple paper choices include: GE 1-ply – GE 2-ply – 1-ply 40# – 1-ply 60# – 2-ply 30/30# – 2-ply 43/43# – 2-ply 50/50# – 3-ply 30/30/30# – 3-ply 30/50/30#.

PAPERplus Chevron

PAPERplus Chevron is the smartest packing filler ever created. With PAPERplus’ pleating technique, Chevron creates a very lightweight and flexible 4″ diameter tube that provides maximum fill with less paper. These paper tubes can be used over and over or recycled.

Another benefit of PAPERplus Chevron is the flexibility of their paper tubes. They are perforated every 3″, allowing you to adjust the packing material length to fit your needs. Chevron is also effective as a cushioning material to protect light and medium-weight products of various sizes.

The PAPERplus Chevron system can be integrated into any packaging process. Chevron is easy to load and extremely mobile, ensuring efficiency for both individual and high speed packing stations. Paper tubes can be created either on-demand (minimizing inventory) or produced in large batches and collected into a Storopack bin.

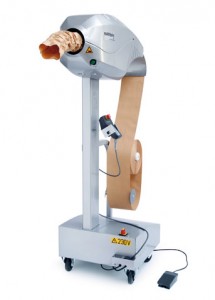

PAPERplus Shooter

If you need void-fill fast, nothing will get the job done like the PAPERplus Shooter. Shooter mechanically creates multi-layer void-fill at 306 – 576 FPM, and proceeds to cut the paper and shoot it directly into the box as well. This replaces slow manual crumpling which will drastically increase productivity, not to mention this enhanced crimping yields a bulkier paper cushion.

In a specially designed carton the paper unwinds from the inside of the roll and is then fed through the PAPERplus Shooter, automatically creating multi-layer.

- Variable speed capability allows fit-for-purpose application and helps control costs.

- Enhanced crimping system traps air to create better void-fill while using less paper.

- Automatic cutting and hands-free foot pedal operation results in faster throughput.

- Paper roll comes in specially designed dispensing carton for easy roll changes.

- Available in tabletop or floor-stand model for any packing environment.

- On-demand option allows for cost-control in batch packaging operations.

- Ergonomic height adjustment.

- Packing flexibility thanks to free rotating head.

PAPERplus Integration

PAPERplus has an efficient and affordable solution for any packaging environment. Storopack’s Systems Integration Department develops a custom-built plan based on your needs. They will carefully analyze your current processes and facility before constructing a plan. Factors that are to be considered include:

- Improve productivity to reduce costs

- Speed and ease of supply material loading

- In-line or off-line packaging

- Ease of handling

- Maximum use of facility space

- Environmental issues

- Accessibility for loading and machine maintenance

- Optimizing ergonomics and output

- Future planning considerations

Upon a thorough analysis, a proposal will be developed that effectively integrates new machines to your facility. You will then have an idea how the machines will be integrated so at to judge for yourself. After approval, Storopack will deliver and install the systems within 6 to 8 weeks.

If you have any questions regarding these PAPERplus systems, feel free to give TwinSource a call at 763-585-1086 or send us a message.

Minneapolis Packaging Products

Technical Functionality Key

Keep these terms in mind when reading about PAPERplus products:

Cushion: Absorbs shock, protects fragile products.

Block and Brace: Steadily holds heavy items or single objects in place inside the box.

Void-Fill: Keeps products from moving within the box by filling empty space.

Wrap: Covers product surfaces to avoid damage on contact and supports all sides for shock protection.

TwinSource Upper Midwest's leading supplier of Industrial products.

TwinSource Upper Midwest's leading supplier of Industrial products.

Good afternoon,

I’m interested in purchasing white chevron paper rolls for the storopack machine. Can someone assist with this. Can you supply these rolls? We need about 50/100 rolls.

Thank you,

Adriana